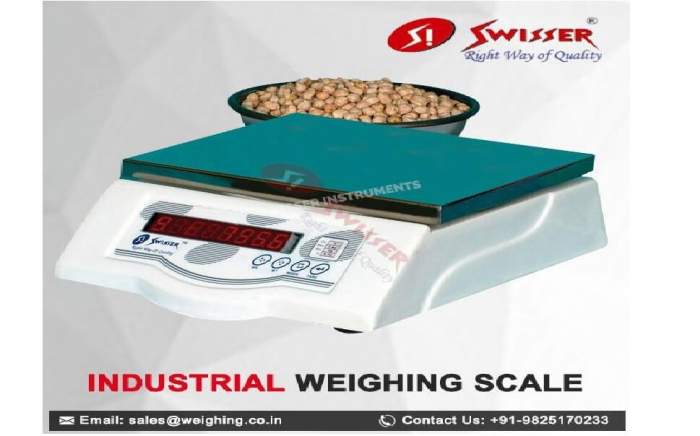

As the name implies, a Weighing Scale is used to measure the load of an object or a person with a predefined scale of measurement. It is the most important equipment for any industry and business.

We are reckoned as India’s trusted Weighing scale Suppliers in India. It works with the use of a strain gauge load cell. The load-cell consists of a set of strain gauges that get deformed as the pressure is applied to them upon. This deformation is measured as an electrical signal and therefore be appropriate for processing.

How does it work?

The operation of an Industrial weighing scale can be divided into two parts. The first being the sensing part and the second, the processing part. The sensing part includes a collection of sensors that measure the weight and convert it into electrical form for processing. The processing part then takes this amplification signal, then converts the analog voltage into a digital form with the aid of a precision Analog to digital converter, and displays it on the LCD for readout. The sensors used for measurement are known as load-cells. The weighing scale arrangement is such that the item mounted on the platform exerts a force on the strategically placed load-cells underneath it. A load-cell is a transducer that converts a force into an electrical signal.

Maintenance

If you employ a weighing machine in your day-to-day life, it’s necessary to make sure that it’s error-free and provides its peak performance. Regular preventive maintenance plays a huge role in prolonging its life.

- Keep it grounded: When using it, ensure it’s placed on a stable, vibration-free floor.

- Regular Inspection: It should be handled with extreme care. Regular inspection should be conducted for signs of wear and tear, damage or corrosion, and wiring of the system. A regular inspection may result in hassle-free functionality. Look for any kind of moisture that may enter the electronics. To prevent further damage or to avoid high maintenance costs, carry out routine checks on your own, and resolve defects as soon as they are found.

- Making Necessary Adjustments: It is natural for the weighing scale to expand and contract a little at different times of the year. This thermal growth requires you to make necessary adjustments for it to give accurate readings.

- Repair: If you discover any damage or corrosion on a scale for safe and reliable operations, a quick repair is extremely necessary.

- Do not overload a weighing scale on the far side of its capability.

- Rough handling might impact its performance. Don’t touch its sensitive scales throughout operations.

- It is important to regularly analyze its battery.

- Do not dismantle or tamper with a scale.

To buy the best available Industrial weighing scale, visit Swisser Instruments Pvt.LTD one of India’s leading Weighing scale manufacturers in India. Feel free to ask any questions regarding this. We will be pleased to serve you.