Finding the right reprocessed PVC compound supplier in the current manufacturing environment can either make you or break your end production objectives. This is a very important decision because the end quality of your products, cost efficiency, and the success of operations can be highly affected by this decision. As the market becomes full of many suppliers, it is sometimes difficult to find those partners who could really comprehend the individual needs of a business.

The incorrect decision may result in quality problems, loss of time in supplies, and loss of financial gains. However, with a good approach and a careful thought, you will be able to form partnerships that would lurch your business into a new height without taking away the best of quality and reliability.

1. Evaluate Technical Expertise and Industry Knowledge

Technical competence of suppliers and their deep industry knowledge is the core of a successful venture with them. An excellent supplier of reprocessed PVC compound must reflect extensive expertise in polymer chemistry, the processing methodology, and the application demands. They must be capable of offering extensive technical specifications, rigorous material testing, and also give professional advice on what compounds to use depending on your requirements.

2. Assess Quality Control Standards and Certifications

Consistency of quality is the most important matter regarding reprocessed PVC compounds since variations may hugely affect the end products of your investments in them. Look at the quality management systems and testing patterns of the supplier and their compliance with global standards like ISO 9001, ISO 14001, or trade-specific standards. A good supplier must also pay close attention to the quality control processes in their production procedure, in the process of selecting raw materials, as well as in the completion and delivery of the end products.

3. Verify Production Capacity and Scalability Options

One should also know how a supplier can produce since this would mean whether they will have the capacity to satisfy your present and future requirements. Consider their production infrastructure, capacity of the available equipment, and their capacity to ramp up production, based on your estimates of your business growth. An ideal supplier must also possess adequate production capacity that will enable it to take your order volumes without affecting the quality or completion dates.

4. Analyze Supply Chain Reliability and Logistics Network

An efficient supply chain management acts as the foundation of quality and efficient material provision as well as delivery services. Visit the logistic capabilities, distribution centers, and transportation partners of the supplier to see that they are able to effectively operate within your geographical locations. Compare their track history in terms of timely delivery, accuracy of shipping, and taking rush orders.

5. Compare Pricing Models and Value Proposition

Although being price competitive matters, using the lowest price only might be of deceptive

value and rather counterproductive. Analyze the overall cost of use that involves the cost of

the product price, costs of transportation, costs of quality, and the potential cost of

downtime in case of material failure. Your provider must be fair enough to provide

transparent pricing, volume discounts, and flexibility in payment terms that are in

conformity with your cash flow needs.

Conclusion

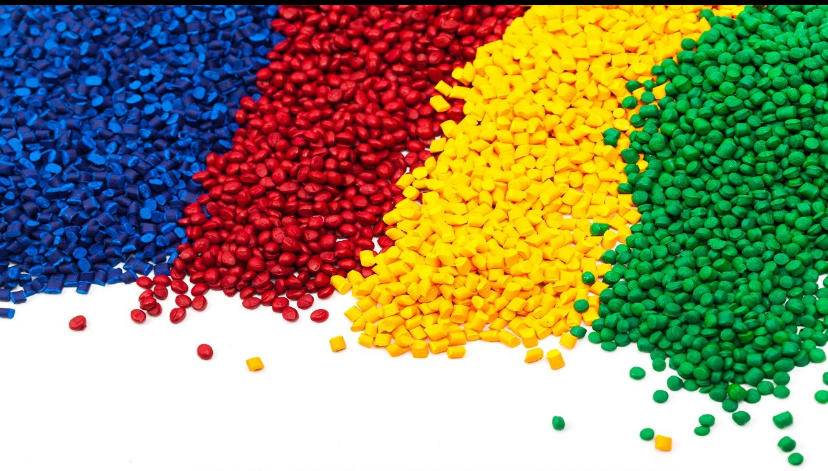

There are numerous factors to consider when choosing the reprocessed PVC granules reprocessed PVC granules supplier of choice, namely: the technical expertise, quality standards, and production capacity, as well as reliability of the supply chain and a positive overall value proposal.

Through a diligent evaluation of these important aspects, companies will be able to develop