The efficient movement of heavy loads is crucial in industries and construction sites. Industrial Chain Pulley Block are reliable tools designed to tackle such tasks. They provide a convenient and safe solution for lifting, lowering, and maneuvering heavy loads in various settings. In this guide, we’ll share with you the tips to choose the industrial chain pulley block and its maintenance tips.

Understanding Industrial Chain Pulley Blocks

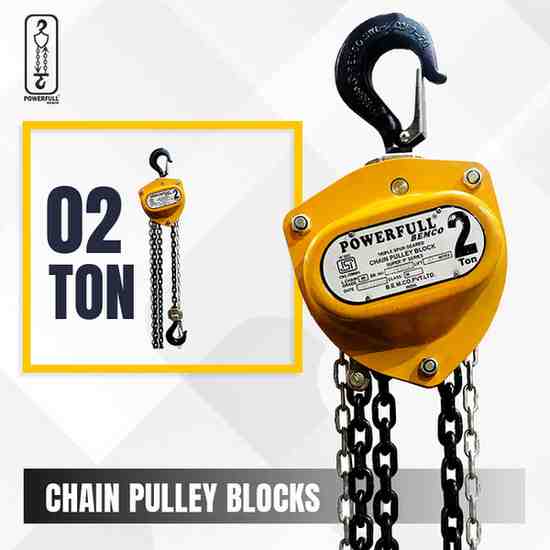

Industrial chain pulley blocks are mechanical devices used for lifting and transferring heavy loads horizontally. They consist of a chain block mechanism, which comprises a chain, hooks, pulleys, and a load-bearing mechanism, and a trolley that allows for movement along a beam or track. These systems can be electrically or manually operated, depending on the specific requirements and available power sources.

Tips on How to Choose the Industrial Chain Pulley Block

Choosing the best industrial chain pulley block necessitates taking into account a number of criteria. Here are some crucial factors to consider when selecting an industrial chain pulley block:

Load Capacity

Determine how much weight the chain pulley block can raise. To guarantee safety and longevity, select an industrial chain pulley block with a load capacity that surpasses your needs.

Trolley Type

Based on your application, determine the sort of trolley you require. Push trolleys and geared trolleys are the two most common types. Push trolleys are handled manually and are best suited for lesser loads, whereas geared trolleys enable smoother movement and are better suited for bigger loads.

Beam Size

Take measurements of the width and profile of the beam where you intend to put the chain pulley block. To guarantee correct fit and safe operation, check that the trolley is compatible with the dimensions of the beam.

Material and Construction

Take into account the environment in which the chain pulley block will be employed. Choose a chain pulley block made of high-quality materials like steel to ensure durability and lifespan.

Manufacturer Reputation

Examine the repute and dependability of the company or brand that makes the chain pulley block. Look for reputable Industrial Chain Pulley Block Manufacturers in India that are recognized for manufacturing high-quality goods and giving excellent customer service.

Budget

Consider your budget while keeping the quality and features you desire in mind. Keep in mind that purchasing a dependable and high-quality chain pulley block is critical for long-term safety and performance.

Common Misuses of Industrial Chain Pulley Block You Should Avoid

Operating a manual hoist necessitates close attention to avoid errors that might have catastrophic repercussions. To help you avoid such mistakes, it is critical to understand and avoid the following typical chain pulley block misuses:

Twisting the Chain

Ensuring the straightness of the chain is vital when using a hoist. Twists in the chain can lead to jamming within the gears, resulting in the hoist stopping midway through the lifting process and potentially causing damage to the load.

Furthermore, chain jams can also harm the internal components of the machinery, leading to the need for new equipment and unnecessary repair expenses to meet daily lifting requirements.

Overloading the Hoist

One common misuse of manual hoists is overloading them. Many individuals overlook this aspect and overload the hoists with excessive and unnecessary weights. While the machine might handle the weight temporarily, its long-term performance will be compromised.

Overloading strains the hoist’s hook and may cause damage to the load itself. Consequently, the usability of the Chain Pulley Block (CPB) is compromised, necessitating its replacement and resulting in additional costs.

Exerting an Excessive Amount of Force

Most of the top Industrial Chain Pulley Block Suppliers in India advise maintaining a loose grip while operating a CPB to avoid potential issues during loading and shifting.

However, many operators make the mistake of exerting excessive force on the chain, which can lead to three potential problems: complete detachment of the chain from the hoist, separation of the chain from the socket, and stretching and straightening of the chain links.

All these issues cause damage to the loads and ultimately disrupt the business process. To prevent such problems, it is crucial to apply the correct amount of force when using a CPB.

Modifying the Chain Hoist

Manual hoists offer complete customization options, but modifying your manual chain hoists is not advisable. Inexperienced operators often tamper with the equipment, such as popping the latch or making other modifications.

Some people even attempt to use CPBs with motors to facilitate lifting, but this is not a sound engineering practice. While such modifications may make lifting loads easier, they are unsafe.

If a third party modifies the machine, the manufacturer’s warranty becomes void. This means that if any issues arise with the hoists, you will not be eligible for warranty services to repair or replace them.

Horizontal Pulling and Angular Lifting

Another common mistake made by workers operating a CPB is improper handling. CPBs are designed for vertical lifting, and any deviation from this can damage the internal components of the block.

An industry-wide misuse often involves not positioning the load directly beneath the CPB and engaging in angular lifting. Prior to commencing any lifting operations, workers must be educated on the correct handling techniques.

Maintenance Tips for Industrial Chain Pulley Block

Regular Inspection

Conduct routine visual inspections to identify any signs of damage, wear, or malfunction.

Inspect the load chain for elongation, corrosion, or twisted links. Lubricate moving parts according to the manufacturer’s recommendations.

Periodic Load Testing

Perform load testing periodically to ensure the chain pulley block can handle its rated capacity.

Follow industry standards and guidelines for load testing procedures.

Professional Servicing

Engage qualified personnel for periodic maintenance and servicing. Any repairs or replacements should be done by authorized technicians.

Conclusion

Industrial chain pulley blocks provide a reliable and efficient solution for lifting and moving heavy loads in industrial and construction environments. By understanding and implementing proper handling practices, workers can enhance productivity and efficiency while minimizing the risk of accidents or damage caused by improper use of machinery. Training plays a crucial role in reducing these risks.

B.E.M.Co. Pvt. Ltd is a customer-focused company, manufacturing and supplying an excellent range of trolley-mounted chain pulley blocks along with chain slings and beam trolleys. Contact us now to discuss your requirements for chain pulley blocks.