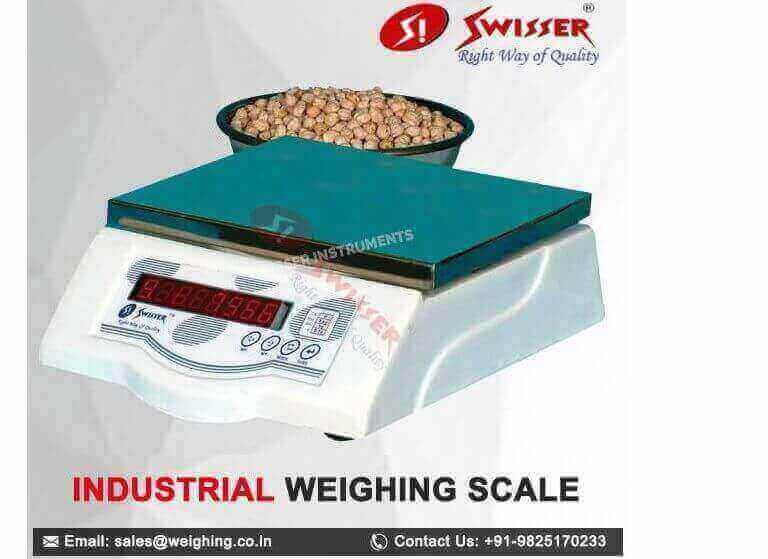

In the modern world of manufacturing and production, accuracy and efficiency are crucial. Industries dealing with bulk materials, such as food processing, pharmaceuticals, chemicals, and logistics, rely on precise measurements to ensure their processes run smoothly and meet stringent quality standards. This is where the industrial Weighing Scale play a pivotal role. These specialized scales are designed to handle heavy loads and provide accurate measurements, making them an essential tool in various industrial applications.

Industrial scales are versatile and come in different sizes, shapes, and capacities to suit the needs of different industries. They are used at various stages of the production process, from weighing raw materials to monitoring and controlling the final product’s weight. Let’s explore some key applications of industrial scales in detail.

Weighing Raw Materials

In any manufacturing process, accurate measurement of raw materials is crucial. Industrial scales are used to weigh incoming raw materials, such as grains, liquids, chemicals, and other components, to ensure that the right quantity is used in production. This helps maintain consistency and quality in the final product. The scales can be designed for different environments, including harsh industrial environments, to withstand the demands of heavy-duty usage.

Batching and Blending

Many manufacturing processes require precisely mixing multiple ingredients to create a final product with the desired characteristics. Industrial scales are used in batching and blending applications to measure and combine materials in the correct proportions. These scales can be programmed to measure specific quantities of each ingredient and provide accurate readings to maintain the correct ratio. This is especially critical in industries such as food processing and pharmaceuticals, where the quality and consistency of the final product are of utmost importance.

Quality Control

Quality control is a crucial aspect of manufacturing processes, and industrial scales offered by Weighing Scale Manufacturer in India play a vital role. They are used to weigh finished products and verify their weight against predetermined specifications. If the weight of a finished product falls outside the acceptable range, it may indicate a defect or inconsistency in the production process. This allows manufacturers to take corrective action and maintain the quality standards of their products.

Packaging

Packaging is a critical step in the production process, and it is essential to ensure that the correct weight of the product is packed into each container. Industrial scales measure the product’s weight and ensure that it matches its intended packaging weight. This helps prevent overfilling or underfilling packages, which can lead to wastage or legal compliance issues. These scales can be integrated into packaging lines to provide real-time measurements, improving the efficiency and accuracy of the packaging process.

Shipping and Logistics

In industries such as logistics, accurate weighing of goods is essential for transportation and billing purposes. To determine their weight accurately, industrial scales are used to weigh trucks, containers, and other large objects. This information is used to calculate shipping costs, ensure compliance with weight regulations, and prevent overloading, which can lead to safety hazards and legal penalties. Some scales are designed specifically for heavy-duty applications, such as weighbridges, which are used to weigh trucks and other large vehicles.

Inventory Management

Effective inventory management is critical for efficient production processes. Industrial weighing scales are used to weigh and track inventory, ensuring that the right materials are available for production. They are often integrated with inventory management systems to provide accurate and real-time data on stock levels, allowing manufacturers to make informed decisions about procurement, production planning, and logistics. This helps reduce stockouts, prevent overstocking, and optimize inventory levels, leading to improved operational efficiency and cost savings.

Safety and Compliance

Safety is a top priority in industrial environments, and industrial scales ensure compliance with safety regulations. Many industries have weight limits and guidelines to prevent accidents and ensure safe operations. Industrial scales monitor and control weights to ensure compliance with these regulations.

Process Optimization

Industrial Platform Weighing Scale are not only used for measurement and compliance but also for process optimization. Manufacturers can identify and address inefficiencies or inconsistencies in their processes by accurately measuring and monitoring weights at various stages of the production process. For example, if there are discrepancies in raw material weights, it can indicate issues with supplier quality or handling processes. If there are variations in finished product weights, it can highlight inconsistencies in the blending or packaging process.

Automation and Integration

With technological advancements, industrial scales are increasingly integrated into automated systems to streamline operations and improve efficiency. To automate weighing processes, many industrial scales can be connected to other equipment, such as conveyors, robots, and control systems. This helps reduce human error, increase accuracy, and improve productivity.

Data Collection and Analysis

Modern industrial scales have advanced features allowing data collection and analysis. These scales can store weight measurements, timestamps, and other relevant data, which can be used for analysis, reporting, and traceability purposes. This data can provide insights into production trends, identify areas of improvement, and help with quality control and compliance efforts. Additionally, some industrial scales are equipped with connectivity features that allow for real-time monitoring and remote access to weight measurements, providing visibility into operations from anywhere in the facility or remotely. This data-driven approach enables manufacturers to make data-based decisions, optimize processes, and continuously improve their operations.

Conclusion

Industrial scales are critical in various industries, facilitating accurate measurement of raw materials, batching and blending, quality control, packaging, shipping and logistics, inventory management, safety and compliance, process optimization, and automation. They are designed to withstand the demands of heavy-duty usage and provide precise measurements crucial for maintaining consistency, quality, and compliance with regulations. With technological advancements, industrial scales are becoming more sophisticated. Features such as automation, data collection, and connectivity enable manufacturers to optimize processes, improve efficiency, and make data-based decisions.

Swisser Instruments Pvt. Ltd. is the one-stop destination for Weighing Scale Supplier in India and is known for its high-end quality.