Weighbridges are excellent instruments for measuring industrial Heavy Goods Vehicles and can provide reliable, precise results to your company if properly maintained. They work under tough conditions and require frequent cleaning and servicing to ensure consistency and durability of weights. Conducting regular, efficient cleaning of your weighbridges will help to maintain their efficiency and reduce the probability of malfunctions happening and impeding your company’s production.

This brief guide will provide you with what you need to know about cleaning and managing your weighbridges to obtain reliably accurate weight measurements.

Why do I need to clean my weighbridge regularly?

Weighbridge offers an accurate means to capture weight data that can help to protect against human error and to prevent fraud. But over time, mud, dirt, and slurry can build-up under&around the weighbridge. This build-up can happen more rapidly depending on the industry your weighbridge is serving and may harm the integrity of the weighbridge. This will lead to early failure of the load cells which will result in a weighbridge being non-available.

How Often Should You Clean and Check Your Weighbridge?

Weighbridge maintenance should include daily, weekly and monthly routines for the best results and it is the responsibility of both the owner of the weighbridge and the preventive maintenance contractor.

Daily Inspection

- Pit mounted weighbridges: Simply carry out a visual inspection of the pit below your weighbridge to identify if there are any build-ups of mud&dirt that may be affecting its performance and functionality. While carrying out these checks, ensure all members of staff involved in the procedure follow the relevant health&safety regulations about working in a confined space.

- Surface-mounted weighbridges: It is similar to that of pit-mounted variants, you observe to see if any materials underneath the weighbridge that potentially affect the measurements it gives. There should always be space between the superstructure and the ground, with no debris fouling the load cell assemblies.

- Rubber T Sections: Some weighbridges have a ‘T’ section rubber fitted on pit-mounted installations. These are designed to prevent contaminants from entering the pit still we advise removing& clean these when possible as it is likely to affect the weighing accuracy.

Weekly Routines

- Weighing checks: Conducting weekly tests will allow you to identify any possible issues with the weighbridge mechanics. For this record measurement by placing a vehicle at one end of the platform and then repeat it in the middle&opposite end. Then collate the data and analyze the readings to identify whether there are any differences in them. Small discrepancies are acceptable however if the readings are more than three divisions apart, your weighbridge may require special maintenance/repair work.

- Surface-mounted weighbridges: here determine if there are any build-ups of debris under/around the load cell assemblies and ensure that they remain unobstructed. Also, ensure to properly remove any unwanted material, taking care not to cause any damage to the load cell cables as this may affect the readings.

Monthly Routines

- Measure the platform to assess if there has been any noticeable movement to its positioning since the last calibration was performed. Carry out an end-middle-end test as mentioned above and note the readings obtained.

- Jet-wash the weighbridge to remove any loose debris and any build-up of material beneath it avoiding direct contact with load cells. If in doubt, contact the expert to prevent needless damage.

- Next, Rebalance (zero) the weighbridge and repeat the end-middle-end test, noting the readings. Finally, compare the outcomes of the two sets of tests to make it easier to identify any obvious issues with the results obtained.

Benefits of weighbridge cleaning:

- Improved accuracy

- Fewer engineer call outs

- Improved reliability

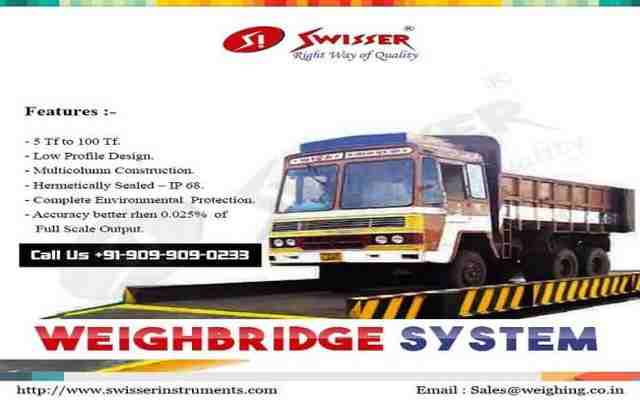

If you are curious about cleaning your weighbridge, contact us. Swisser Instruments provides a range of services including the supply, repair, and calibration of industrial weighing scales. We are leading weighbridge Manufacturers in India. If you’re interested in our services, please contact us.